#Guy wire inspection software#

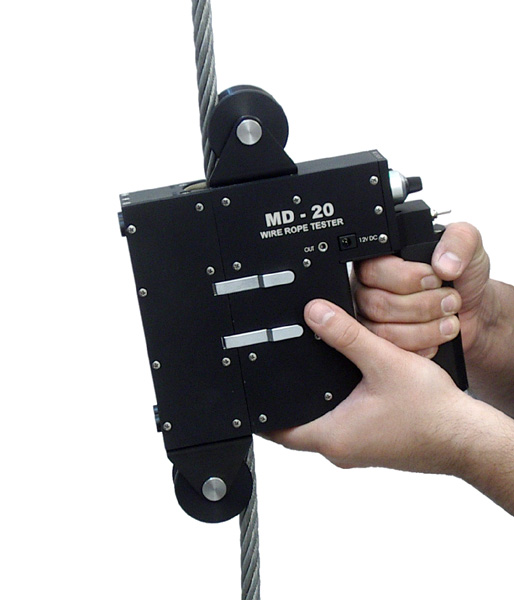

On the return of the recorded back to ground level it is connected to a laptop where the data is retrieved for analysis and through a software program the data can be interpreted from a line graph to distinguish the condition of the guy wire, indicating any defects that are present.Īs well as the identification of internal and external deterioration of a wire rope, analysis of MFL survey results can also allow the identification of the expected remaining lifespan of a guy wire rope enabling Client’s to plan well in advance for the replacement of a guy wire system. A recording device is then connected to the measuring head which analyses the information from the measuring head as it pulled along the guy wire. The MFL measuring head comprises of two electromagnets which is then mounted onto the guy wire. External defects can be seen visually, both internal and external defects are detected with the use of the MFL equipment.

Carrying out both inspection methods allows for a complete analysis of the guy wire condition. SCG-DOW Chemicals operations in Thailand tasked SYNTEX with the detailed inspection and tension checking of a 260ft (80m) flare stack guy wire system alongside a riser verticality survey and pressurised application of a protective wire rope lubricant and guy re-tensioning.Īs part of the inspection criteria SYNTEX carried out a visual inspection along with a Magnetic Flux Leakage (MFL) survey.

SYNTEX carries out inspection and maintenance services to guyed structures throughout the U.K., Europe and Asia. Client: Dow Chemical, Thailand Location: Map-Ta-Phut Site, Rayong Project: Flare Guy Wire System Maintenance and Inspection

0 kommentar(er)

0 kommentar(er)